Over 35 years

of experience

With close to 200 installations operational on 5 continents in 47 different countries you are in reliable hands with Pneumix Injection Units BV.

10+

Products

35+

Years of experience

200

Installations operational

5

Continents

47

Countries

Our history

1988

Founded, selling air compressors and air tools, plus sandblast vessels from the start.

1993

Designed the first loader on behalf of UOP for French refinery. This loader was equipped with an electronic weighing controller and operator panel.

2004

Pneumix designed its first multi ingredient loader enabling refineries to add additives and catalyst simultaneously.

2006

Pneumix holding sells its cleaning and air tools business. Pneumix Injection Units continued as fully focussed catalyst and additive loader designer / manufacturer for FCC.

2008

Sold more than 100 additive and catalyst loaders around the world.

2024

Supplied almost 200 systems to 98 FCCU plants in 48 countries around the world.

Our method

1. Technical visit

Technical visits prior to the installation of the addition device to determine the optimal location of the P.A.I.S. units and design the proper connections to existing storage hoppers.

2. 3D Drawing

Based on the site visits or provided information Pneumix can provide 3D drawings to minimize engineering from the refiners side.

3. Technical discussion

Technical discussion and prepare offer that suits clients demands.

4. Testing

After official order the loader will be completely build and tested in Pneumix workshop.

5. On site supervision

In most cases refinery will install P.A.I.S. units with their local contractor. On request Pneumix can supply on site assistance / supervision during erection / installation.

6. Start-up and supervision

Start-up, commissioning and training of the operators and technicians on site.

7. Continuing support

Provide continuing support and maintenance for all clients to assure optimum performance.

8. Scheduled service visit

If interested we drop by for yearly scheduled service visits to perform preventive maintenance at your location.

Products

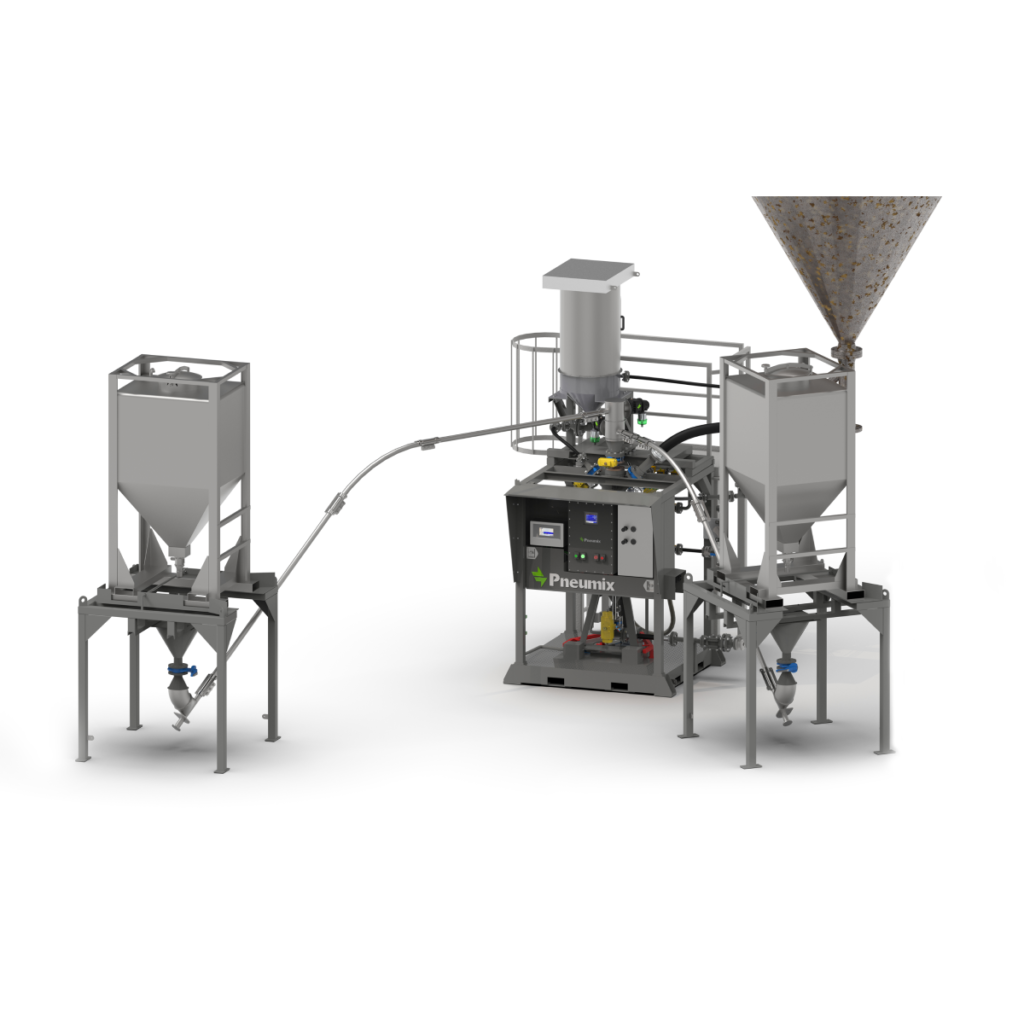

Catalyst Loaders

Our Catalyst Loaders are designed and developed to easily install below existing storage hoppers. Our...

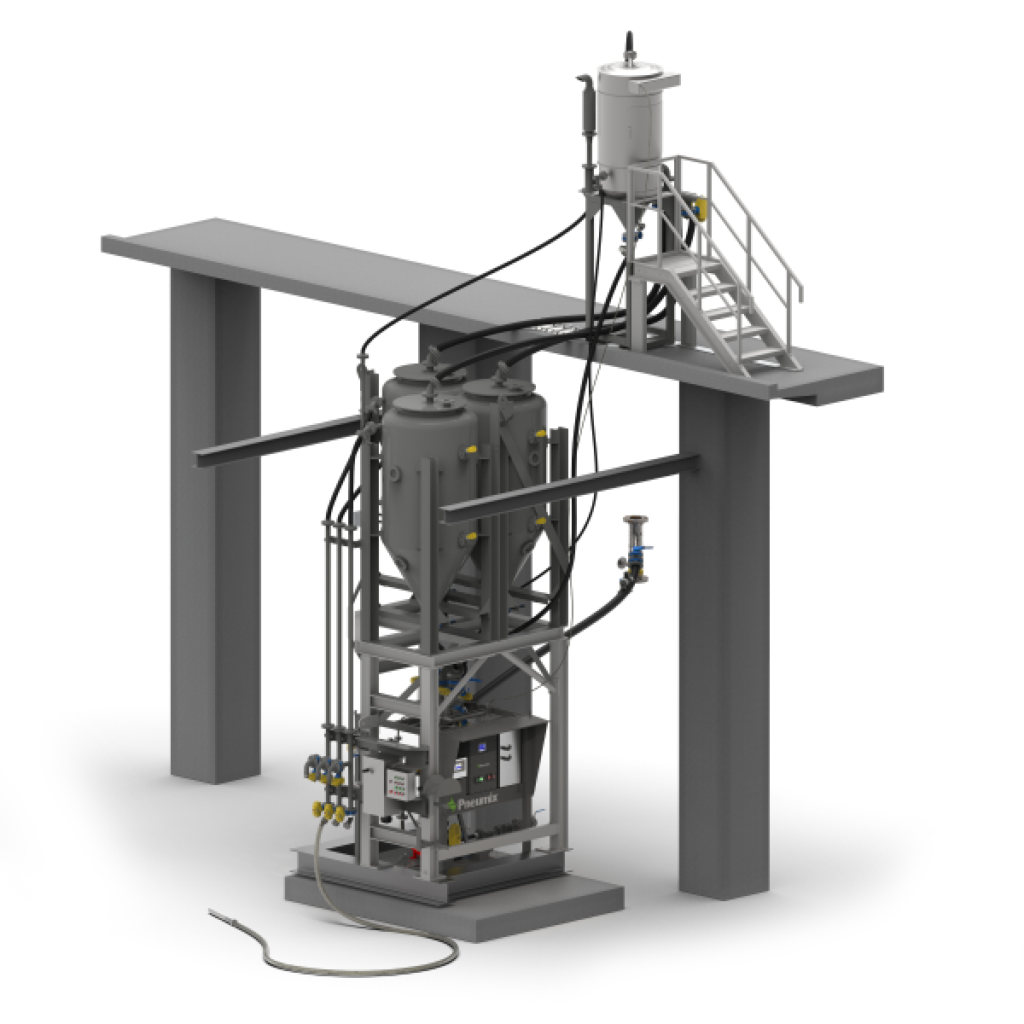

Additive Loaders

Our Additive Loaders are designed and developed to easily transfer the Catalyst or Additive through...

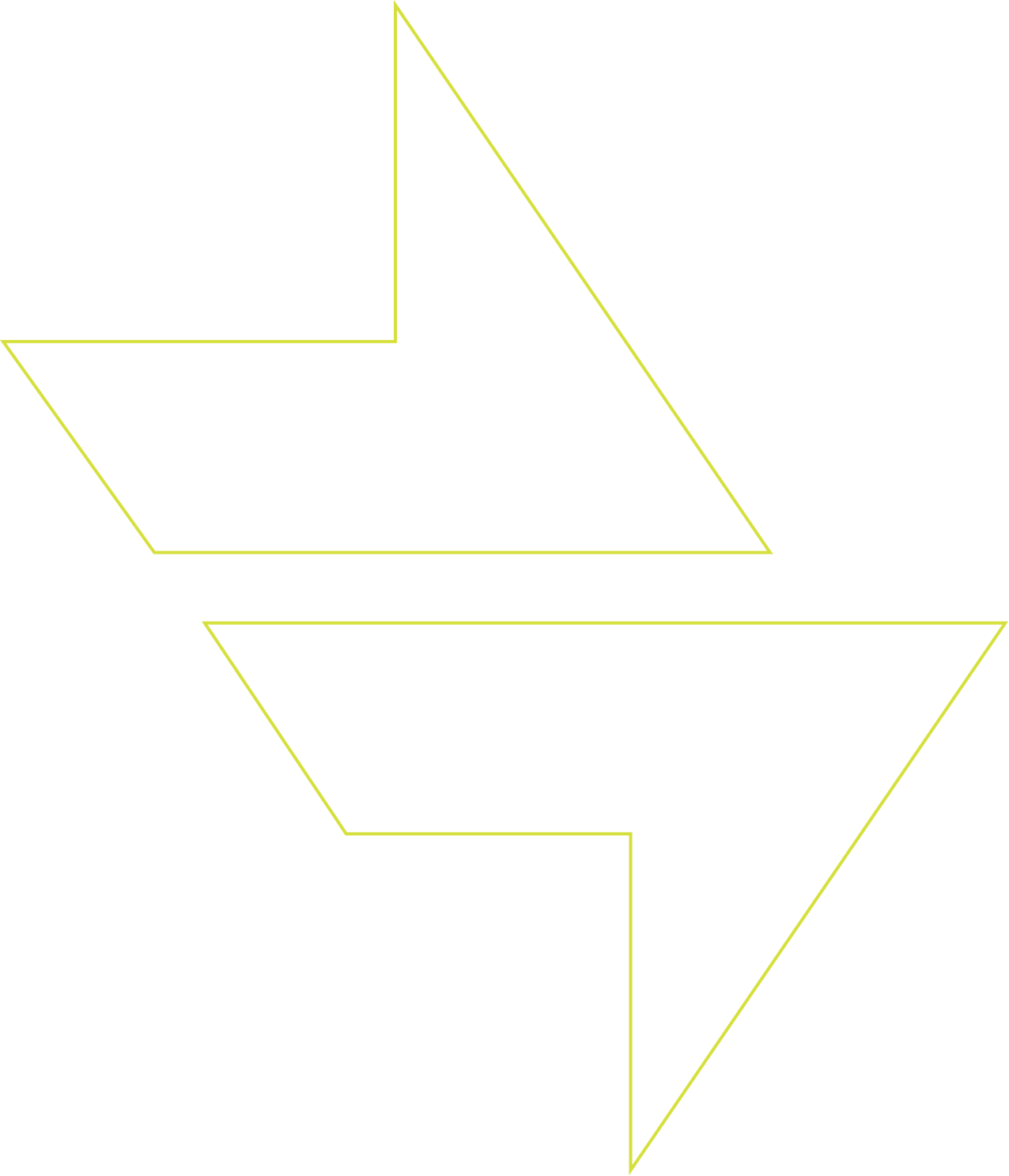

Multi Ingredient Loader 1.0

Our Multi Ingredient Loaders are designed and developed to meet the requirements of refineries nowadays....

Multi Ingredient Loader 2.0

Our Multi Ingredient Loaders are designed and developed to meet the requirements of refineries nowadays....

Expander cleaning unit

Fine catalyst particles, typically less than 1 micron in size, have a tendency to collect...